One screw is removed from the front of the stock.

And the rear trigger guard screw is removed.

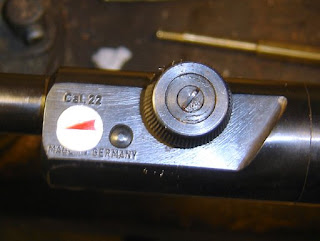

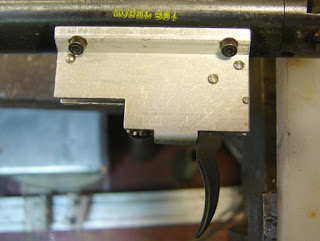

This is where identification of the air rifle gets a bit murky. Printed in yellow ink is "Model 8?1" Not sure if it's a three or a five or what.

The Blue Book of Airguns lists the following Hy-Score model numbers for Hammerli made rifles:

Hy-Score 821, 833SM, 894 - sidelever rifle made by Hammerli of Germany

Hy-Score 833 - Hammerli Model 10 (Puma Model 497)

Hy-Score 894 or 894 Sport - Hammerli Model 4 (Puma Model 490)

However in looking at the section on Hammerli rifles none are listed in .22 caliber.

Since the rifle does not have anti-beartrap provision (but more on that later), it is likely to be a 490 series of Puma, rather than a 400.

Likewise Walter's "The Airgun Book" does not list a Hammerli in .22

It lists the Hy-Score 821 as being equivalent to a Hammerli Model 2 (Puma 495)

But that middle digit doesn't look like a "2" to me. I'm just going to live with the mystery.

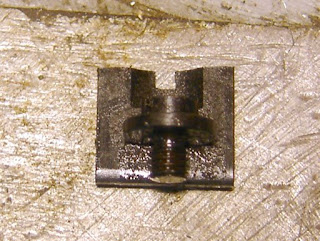

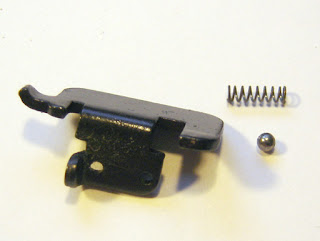

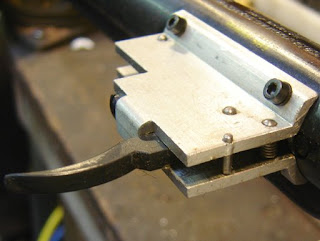

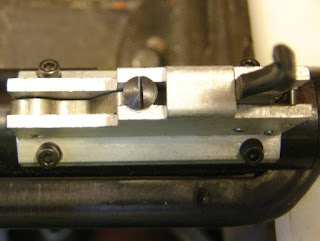

Another mystery, the trigger unit looks either like a home made replacement housing (a well made replacement) or a prototype.

The dowel pin holding the trigger spring was drilled a little off, but it doesn't seem to matter.

I have no idea what any of the adjusting screws do.

A couple more views.

Not a bodged together housing by any means.

I think the pin started to push out because it wasn't secured in the other side. I fixed that.

Moving on...The pin for the cocking lever was pressed out.

And the cocking lever disengaged from the piston and housing.

I mounted the remainder in the spring compressor.

And punched out the end cap retaining pin.

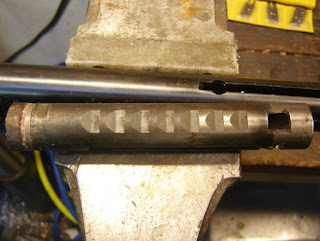

This is how much preload the spring has.

See what I said about the anti beartrap? Those notches are presuambly for the anti beartrap mechanism, but there was nothing to bear against them.

On to part 2