On I go…

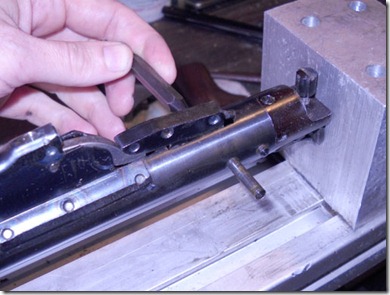

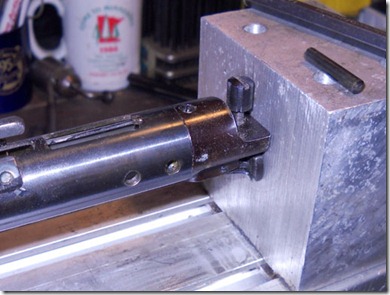

That extremely annoying pin, which the trigger spring rests on, prevents removal of the cocking lever. It is peened on both sides.

So I carefully filed one end until I could punch it out.

I’m not sure why there’s a tapered flat on the pin, possibly to clear the cocking lever arm? Did I mention I hate that pin?

The barrel assembly removed.

The piston slid out easily.

That is not the proper lubrication for a smoothly operating spring piston airgun.

Piston seal removed.

The seal is in great shape.

Looks like they welded the end of the piston on and probably tempered it.

As the other end of the piston sear is likewise oxidized and probably tempered.

The end plug and spacer.

The (for lack of a better word) transfer bar is retained by an extremely peened pin and I decided there was no need to remove it.

There’s a dowel pin with a round nose that sticks out of the end plug. It sets the amount of sear engagement.

It bears on the central part of the sear assembly.

The pin stickout is controlled by a screw in the plug. The pin, logically, sticks out more with the screw screwed in…

…and less with it screwed out.

The conical tip of the screw moves the pin laterally.

Now to clean out all the old grease and reassemble.