Just a bit more

Two pieces joined together. The use of sheet metal in this design is interesting.

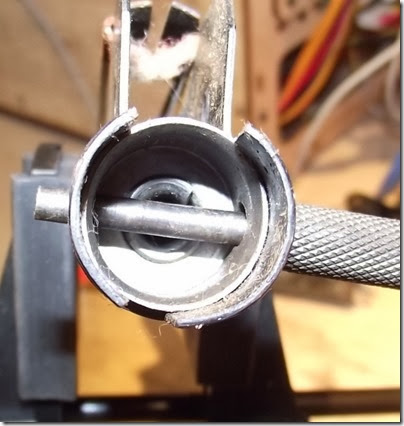

The spring is a bit wiggly…also there is little if any lubrication evident.

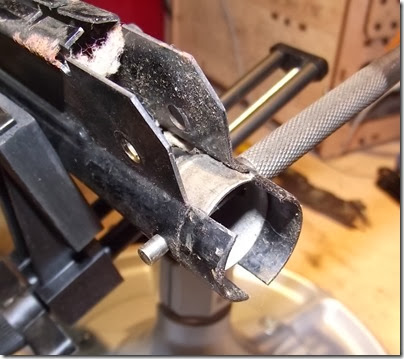

The cocking arm is captured by its little ears.

The cocking arm slides out the back end of the receiver tube.

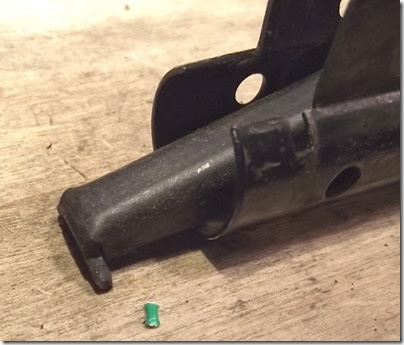

The barrel detent. Staked in place.

The piston, also made entirely of sheet metal, welds and rivets.

Oh, there’s some lube, reduced to putty by age.

The leather piston seal is riveted in place. That is inconvenient. I hope I can massage it into shape in place.

It doesn’t look as bad now, although that leather is really pliable.

I pried the breech washer out.

Ii was backed by a cardboard domed shim.

Interesting. The seal should be fine for reuse.

The breech end. The barrel is brass (or a yellow alloy of some sort). The entire barrel assembly is best left as-is I think.

That’s all the parts. Now to clean, steel wool the rust, lube and reassemble. Not happy about the spring but I don’t have a spare that size. May hit the hardware store and see what they have.